Quest Engineering Solutions is a leading provider of materials testing and many other testing services.

Material Analysis Testing is used to identify the basic properties of materials. Determining strengths and weaknesses of a material aids in more effective and functional design and production of materials. Some basic material analyses include tensile and compression.

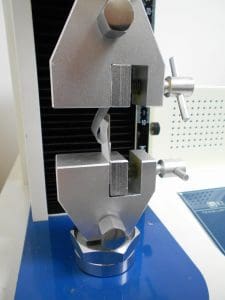

Tensile Testing: Tensile testing determines a product’s resistance to being pulled apart. Outward force is applied at each end of the material to generate tension.

Compression: Compression testing determines a product’s integrity when subjected to compacting. Inward force is applied at two points of the material to create compression.

Tensile and compression testing are also referred to as Pull/Push testing.

Common Materials Tests:

- MIL STD 202

- MIL STD 810

- ASTM F88

- ASTM D638

- ASTM D882

- ASTM D412

- and more!

Quick Links